Benefits And Downsides Of Vehicle Plastic Components Shot Molding

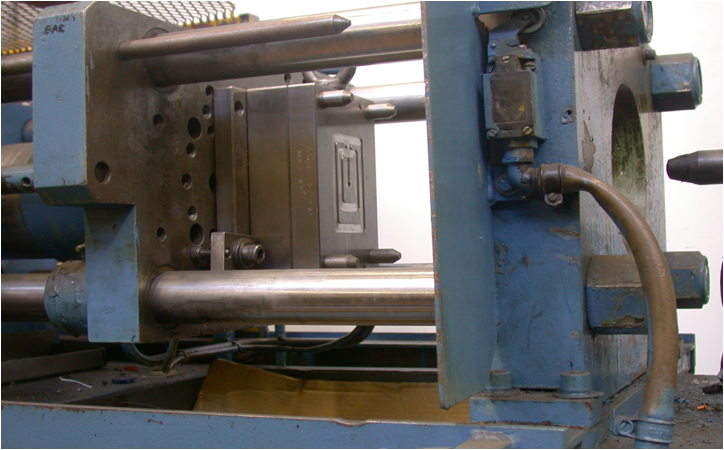

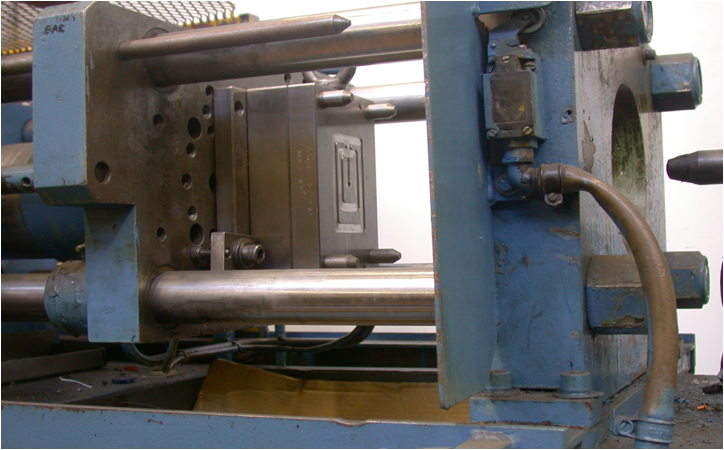

Are you wondering if there are any disadvantages of injection molding? Injection Molding method is a well-known manufacturing process that is commonly used by various manufacturers. It is not a new method, shot molding has been made use of for several years. There are a lot of points around you that are made from plastic utilizing injection molding. However, in existing times, car manufacturers have actually begun to use it for generating auto components. There are several benefits and disadvantage of this technique. In this review, we have highlighted some of the advantages and disadvantages of automobile plastic components shot molding.

Injection Molding method is a well-known manufacturing process that is commonly used by various manufacturers. It is not a new method, shot molding has been made use of for several years. There are a lot of points around you that are made from plastic utilizing injection molding. However, in existing times, car manufacturers have actually begun to use it for generating auto components. There are several benefits and disadvantage of this technique. In this review, we have highlighted some of the advantages and disadvantages of automobile plastic components shot molding.

Read additionally to know more concerning the shot molding.

Benefits of Injection Molding

Right here are few of the advantages of using shot molding for plastic auto parts.

Affordable Option

One of the advantages of injection molding is that it is a cost-effective technique. The procedure of injection molding is automated, it indicates that you will not need to utilize different employees to supervise various production process. The maker will certainly generate a uniform item in mass quantity. This will help reduce the production cost and also labor price.

Effective

Another benefit of using cars and truck plastic shot molding strategy is that it is an reliable method for manufacturing. As soon as the mold and mildew is produced, it will certainly take couple of seconds to make the components. This makes it possible to run the machine night long. Because of this, you could give a plastic part to the market quickly.

Use of Variety of Materials

With the innovation in modern technology, it is feasible to make use of a wide variety of plastic materials for shot molding. There are various types of plastic, several of the plastics could boost the toughness of the product. All the plastics can be utilized for injection molding in order to manufacture custom vehicle plastic components.

Drawbacks of Injection Molding

Have a look at the disadvantages of using shot molding for car parts.

High Initial Cost

Among the disadvantages of injection molding is that it will certainly be expensive to obtain equipment prepared for injection molding. You will certainly need to provide training to among your workers to oversee its operations. This could be expensive for car suppliers.

Part Design Limitations

An additional drawback of injection molding is that there are restrictions relating to the part design. This strategy is separated into 2 parts. When the component prepares, the components have to be pulled apart from releasing the product. Every component has to be created individually without openings. So, it gets difficult to take care of the injection molding process.

Overall, we, at RJC Mold, supply the very best automobile plastic parts in China car parts injection molding. We have actually furnished our facilities with the sophisticated technology that assists us in manufacturing high quality parts. We could supply the benefits of auto plastic component injection molding without any drawback. We have experience and skills to give sturdy auto plastic components. If you have any type of question or need any aid, get in touch with our customer service experts.

We have experience and skills to give sturdy auto plastic components. If you have any type of question or need any aid, get in touch with our customer service experts.

Injection Molding method is a well-known manufacturing process that is commonly used by various manufacturers. It is not a new method, shot molding has been made use of for several years. There are a lot of points around you that are made from plastic utilizing injection molding. However, in existing times, car manufacturers have actually begun to use it for generating auto components. There are several benefits and disadvantage of this technique. In this review, we have highlighted some of the advantages and disadvantages of automobile plastic components shot molding.

Injection Molding method is a well-known manufacturing process that is commonly used by various manufacturers. It is not a new method, shot molding has been made use of for several years. There are a lot of points around you that are made from plastic utilizing injection molding. However, in existing times, car manufacturers have actually begun to use it for generating auto components. There are several benefits and disadvantage of this technique. In this review, we have highlighted some of the advantages and disadvantages of automobile plastic components shot molding.Read additionally to know more concerning the shot molding.

Benefits of Injection Molding

Right here are few of the advantages of using shot molding for plastic auto parts.

Affordable Option

One of the advantages of injection molding is that it is a cost-effective technique. The procedure of injection molding is automated, it indicates that you will not need to utilize different employees to supervise various production process. The maker will certainly generate a uniform item in mass quantity. This will help reduce the production cost and also labor price.

Effective

Another benefit of using cars and truck plastic shot molding strategy is that it is an reliable method for manufacturing. As soon as the mold and mildew is produced, it will certainly take couple of seconds to make the components. This makes it possible to run the machine night long. Because of this, you could give a plastic part to the market quickly.

Use of Variety of Materials

With the innovation in modern technology, it is feasible to make use of a wide variety of plastic materials for shot molding. There are various types of plastic, several of the plastics could boost the toughness of the product. All the plastics can be utilized for injection molding in order to manufacture custom vehicle plastic components.

Drawbacks of Injection Molding

Have a look at the disadvantages of using shot molding for car parts.

High Initial Cost

Among the disadvantages of injection molding is that it will certainly be expensive to obtain equipment prepared for injection molding. You will certainly need to provide training to among your workers to oversee its operations. This could be expensive for car suppliers.

Part Design Limitations

An additional drawback of injection molding is that there are restrictions relating to the part design. This strategy is separated into 2 parts. When the component prepares, the components have to be pulled apart from releasing the product. Every component has to be created individually without openings. So, it gets difficult to take care of the injection molding process.

Overall, we, at RJC Mold, supply the very best automobile plastic parts in China car parts injection molding. We have actually furnished our facilities with the sophisticated technology that assists us in manufacturing high quality parts. We could supply the benefits of auto plastic component injection molding without any drawback.

We have experience and skills to give sturdy auto plastic components. If you have any type of question or need any aid, get in touch with our customer service experts.

We have experience and skills to give sturdy auto plastic components. If you have any type of question or need any aid, get in touch with our customer service experts.Created at 2019-07-15

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE